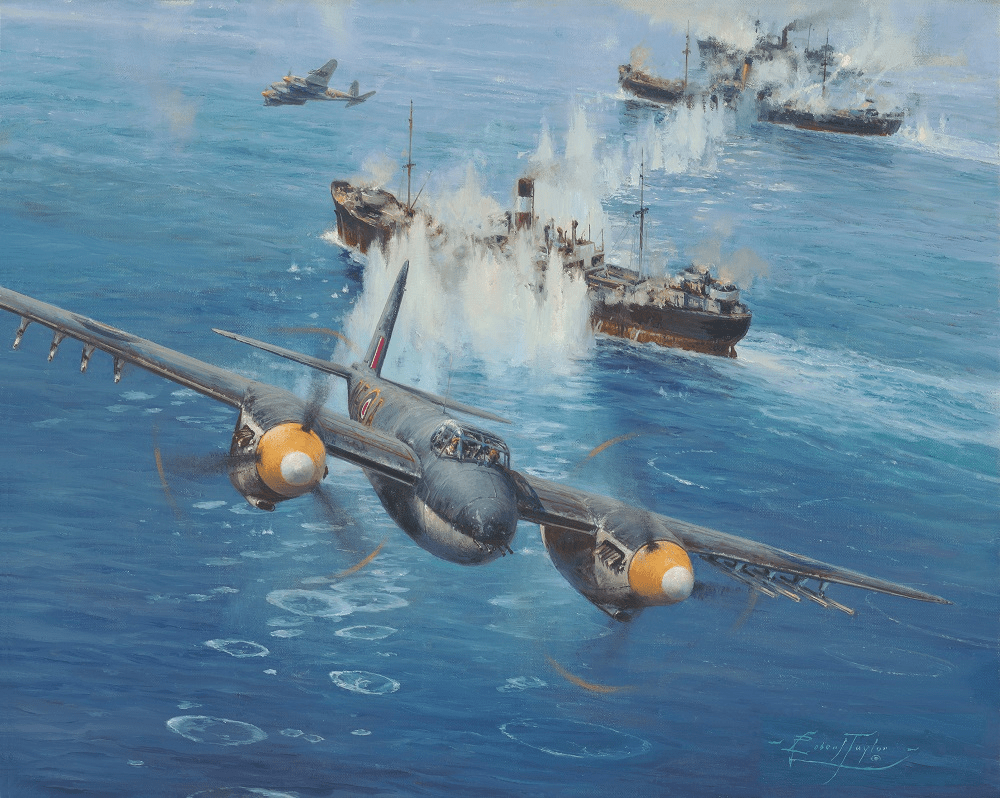

At this years RIAT (Royal International Air Tattoo), we popped along to meet the team behind ‘The People’s Mosquito’ to check out the amazing work they are doing to build Mosquito RL249 in its spiritual home, here in the UK.

It all started in 2018 where a group of dedicated people came together to found ‘The People’s Mosquito’ charity to build the Mosquito, after a 12month period of analysing a unique and vast De Havilland technical archive, and then preserving, assessing and cataloging every original De Havilland technical drawings, digitally copying each and every document.

The People’s Mosquito has the largest and most comprehensive collection of Mosquito-related technical data anywhere in the world. Records stretch from the development of the Mosquito prototype W4050, in 1940, through to late-life modifications made by BAE Systems in 1996.

In February 2018, the charity selected Retrotec Ltd, one of the world’s premier aircraft restoration providers, as lead supplier responsible for overseeing the restoration, testing and final airworthiness acceptance.

Retrotec’s reputation for the highest standards of authenticity is recognised all over the world. Under the expert guidance of Guy Black, Retrotec has established a reputation for delivering some of the most sympathetic aircraft restorations in the world over the past 20+ years.

To continue the dedicated hard work of the charity and Retrotec, The People’s Mosquito chairman & trustee John Lilley has wrote an open letter appealing to the public to support the charities urgent emergency wood appeal.

URGENT – EMERGENCY WOOD APPEAL

Your Help Please – Due To A Time-Limited Donation

Can we achieve £30,000 in additional funds in only a few weeks?

Help us to save £9,000 in costs!

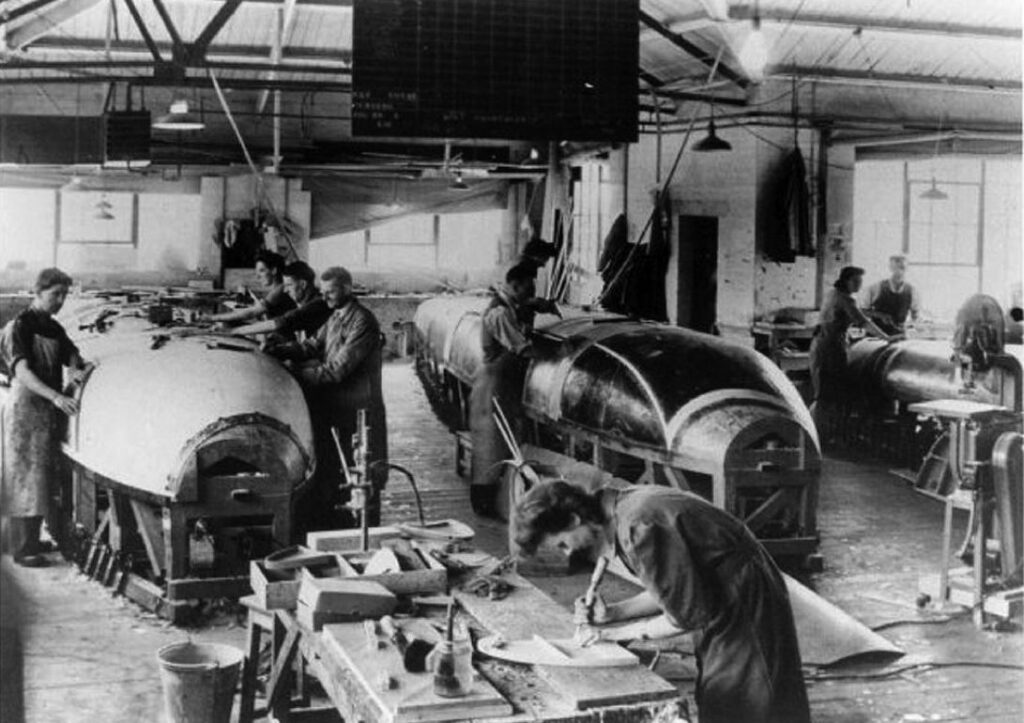

We are pleased to inform you that we have secured a recent donation of specialist glue, a phenolic resin used to bond the three layers of 0.5mm, Grade A veneers that form the 1.5mm inner and outer fuselage plywood skins. Unfortunately, this glue has a limited shelf life!

We have a rare opportunity to accelerate the build and beat the expiry date! But also save valuable funds further down the production line.

With your help, we could move quickly to purchase the plywood and bring the planned fuselage skinning forward, thus saving the £9,000 value of the donated resin from the end cost of the project. Valuable funds we can use on other parts of the manufacture.

We would like to produce all of the 1.5mm and 2.0mm diagonal and straight plywood required for the fuselage in one go, as the benefits are clearly significant.

If every single supporter who opens this letter is able to gift £20 (or more), then we will achieve this target, and the work can continue uninterrupted.

Click HERE to see how you can support this urgent appeal and make a donation. Donate now and we can accelerate the build & save.

Thank you for all your support to help us build in Britain!

Leave a comment